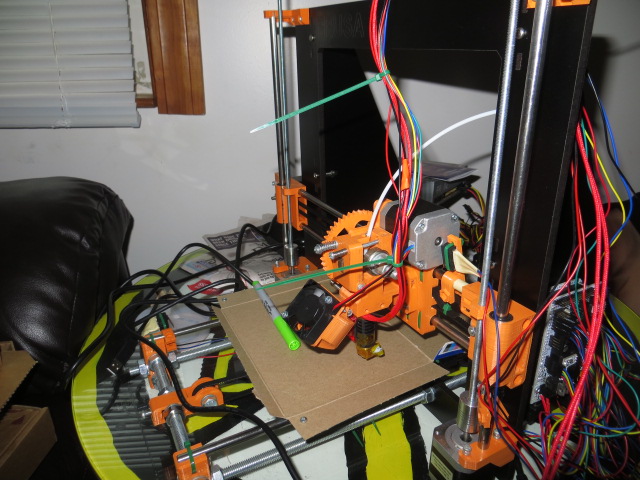

This printer was designed and built in 2014 after 2 years of watching and learning about the 3D printing community.

I chose the I3-rework for its abundance at the time as well as the basic simplicity of the parts needed. After a few eBay purchases for the 3D printed parts, motors, and electronics, a few more on Amazon for the ramps board and belts, I made a trip to the local hardware store. There, I was able to source the nuts, bolts, and threaded rods but couldn’t find 8-mm smooth rod anywhere that wasn’t prohibitively expensive. After visiting a friend for an unrelated project, we happened to look through his basement and found some metal in his father’s stock rack that looked correct. Taking it home it was a perfect 8 mm and is still installed on the printer to this day.

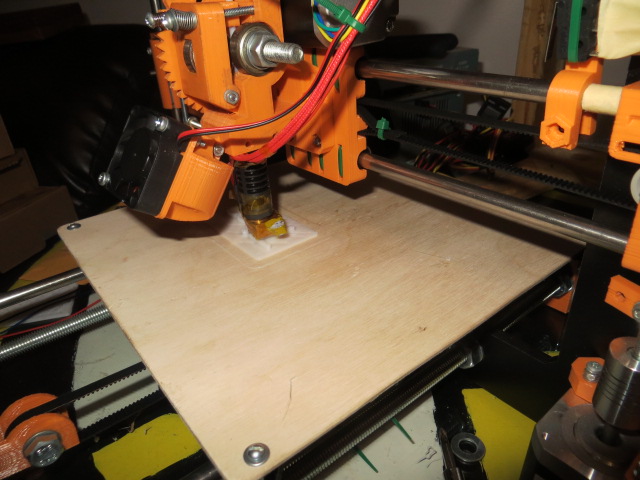

Once the printer was assembled I started to learn more about why the prints were failing.

- The hotend cooling fan actually needs to be ON to properly cool the hotend and prevent jams.

- Bed leveling is a thing

- Prints stick to thin plywood AMAZINGLY… even a bit TOO well and they NEVER come off.

My next addition was going to be a better bed leveling setup and a heated build plate with a proper build surface.